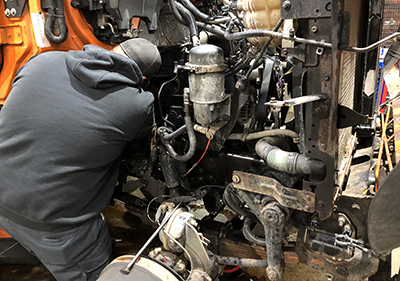

Clint Imker, heavy equipment mechanic, replaces an engine exhaust manifold. Photo by Rick Vollan |

By Joseph Palmersheim

It takes a lot of team work to keep MnDOT’s equipment on the road.

There’s fuel to filled, fluids and bulbs to check and windshield wipers to maintain, to name a few things. There are various electrical, mechanical and hydraulic systems that bring each of MnDOT’s 800 plows and 400 other snow-fighting machines (like loaders, blowers, dozers, graders and large tractors) to life.

When it’s cold outside, it doesn’t take much for things to go wrong. Air brakes leak, blades dull, hydraulics fail and hoses wear. Nothing mechanical performs better when it is cold. Sometimes, it’s a challenge just to find the problem when it’s encased in inches of solid road ice on the bottom of a freezing plow.

This service and repair work doesn’t happen by itself, and when the plows are out around the clock during a snow event, the blizzard of needed repairs can match the intensity of the snow outside. MnDOT’s 155 mechanics are responsible for maintaining the machines that keep the roads clear.

Most of the repair work is done in maintenance shops, but sometimes, it’s done where it needs to be done.

“Our field technicians are out there in the worst possible elements,” said Rick Vollan, the District 7 shop supervisor in Windom, who started as a mechanic 25 years ago. “I can speak from personal experience here, as field mechanic for seven years. I’d be lying on my back, under a truck, in the middle of a blizzard. It's very challenging at times. We do everything we can do to get the truck back in service quickly and safely, but for some breakdowns we have to call a towing company.”

MnDOT’s maintenance shops each have a supply of commonly used spare parts. Windshield wiper assemblies are crucial – if a truck can’t see during a storm, it’s no good to anyone. The blades are easy to find, Vollan said, but finding the wiper arms, motors and other parts can be a challenge for the older trucks in the fleet. Sometimes, the parts need to come via a shipping service, which can take days. When the snow is coming down, that’s time you don’t have.

“This really is a well-orchestrated dance,” said Jed Falgren, state maintenance engineer. “It’s absolutely a blast to watch [our entire team] when things are clicking.”

Crews track repairs and maintenance through the M5 Fleet Management program. Supervisors can use the data there to evaluate vehicle availability and upcoming maintenance. Sometimes, if the situation calls for it, crews will perform repairs to get the vehicle safely through the storm, and then complete the necessary long-term maintenance work once the snow stops.

“In the repair world, our Super Bowl is now, and we do our best to get our trucks back out to our operators,” Vollan said. “That may involve ‘Band-Aids,’ or fixes we can do now, immediately. We document everything, like what we'd done initially, and what we need to do later when we have time. For example, if a truck comes in and needs a specific part that I have to order, I can fix it in a way that gets it back out on the road. When the part arrives, I'll call that truck back in and we can fix it.”

Every blizzard stops eventually, and plowing the snow off the road is simply the first step in the battle. Crews also have to widen lanes, haul snow away from spots that are saturated with it, and plan ahead to ensure there’s a place for snow from the next storm to go. (After the recent snow event at the beginning of the month, when snow stopped falling on Jan. 4, crews in some districts were out for several more days doing this critical follow-up work.)

And the next time the snow falls, the process starts again. The plows will be out and their mechanic crews will be working to keep them there.

“You do the best you can, and when you get that equipment working again, it’s really gratifying,” Vollan said. |